Puricelli HPL slab manufacturing technologies – what’s behind the names and where are they best used?

References

Puricelli HPL laminates are a recent addition to our range, but they’ve already gained popularity and recognition among designers, architects, stonemasons, and individual clients. While the resistance and durability of these slabs are fundamental and expected features, the brand goes a step further – diversifying its production processes and developing dedicated technologies tailored to specific applications.

A.BAC – hygiene and safety first

In environments where hygiene is essential – or mandated by strict regulations – such as kitchens, bathrooms, restaurants, medical or educational facilities, slabs produced with A.BAC technology are the perfect solution. An antibacterial coating limits the growth of microorganisms on the surface and reduces their presence by up to 99.9%, as confirmed by tests on bacteria like Staphylococcus aureus and E. coli. These antibacterial properties remain effective throughout the product’s lifetime and do not diminish with regular cleaning.

MOREWOOD – the warmth and authenticity of wood... without the wood!

For those who love the warmth and character of wood but are concerned about its durability, Puricelli has created a unique solution. MOREWOOD technology faithfully replicates the appearance and texture of high-quality wood species. The surfaces are resistant to moisture, water vapour, stains, and scratches, making them ideal for interiors subject to heavy use.

MOREMATT – surfaces for special tasks

Matte surfaces remain as popular as ever – and it’s easy to see why. They offer understated elegance and are easy to maintain. Puricelli takes this further with a nano-based micro-sponge technology that enhances durability. MOREMATT surfaces are soft to the touch, velvety matte, fingerprint-resistant, and easy to clean. Minor scratches can be easily removed with a simple melamine sponge.

MIXIS – a sparkle that never goes out of style!

MIXIS technology is designed for those who want a finish with a bold character. A thin layer of metal adds a refined shine and depth to HPL slabs without compromising their performance. This is an ideal solution for interiors where visual impact is key.

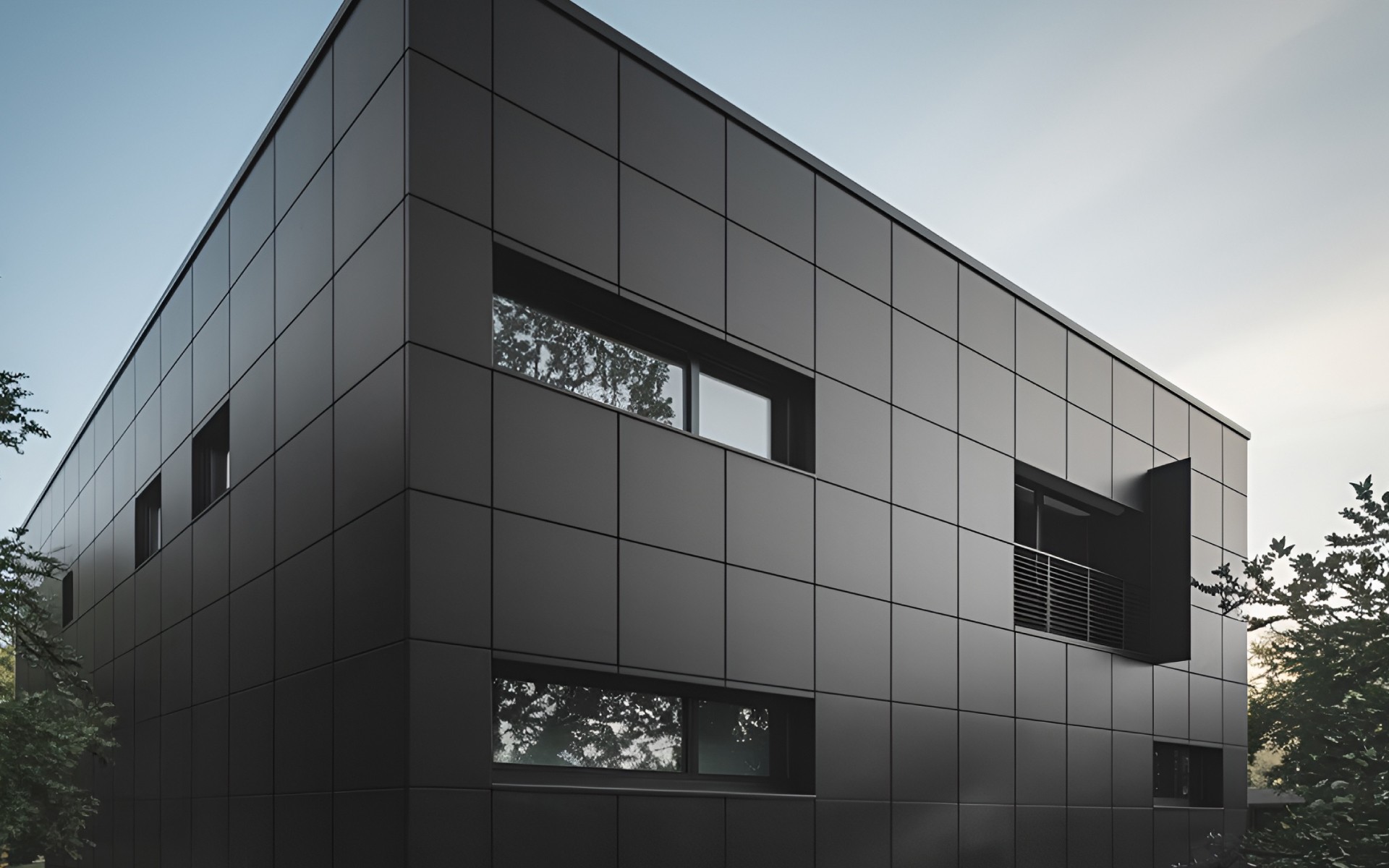

N.EXT – for the outdoors, for summer, for years to come

When it comes to outdoor use, resistance to changing weather conditions is crucial – and that’s where N.EXT technology excels. HPL slabs in this series, designed for façade applications, feature a double-sided thermosetting resin coating that protects against UV radiation, moisture, and extreme temperatures. They are fire-resistant, antistatic, visually appealing, and finished with an anti-graffiti layer that prevents unwanted markings. Perfect for use on residential or commercial buildings, balconies, schools, fences, benches, gates, or outdoor furniture.

Thanks to its wide array of technologies, Puricelli HPL is no longer “just laminate.” Each production method is thoughtfully developed with specific needs and environments in mind – from commercial interiors to outdoor façades. These materials are not only visually appealing but also meet real-world design challenges. Whether your priority is hygiene, resistance, aesthetics, or long-term durability, with Puricelli, you don’t have to choose – you get it all.

Check also: HPL Puricelli and large ceramic slabs Keralini as modern materials for facades