As a result of cooperation with construction companies and substructure manufacturers, the installation of our materials (HPL panels and large-format quartz sinter KERALINI) on facades is most commonly done using:

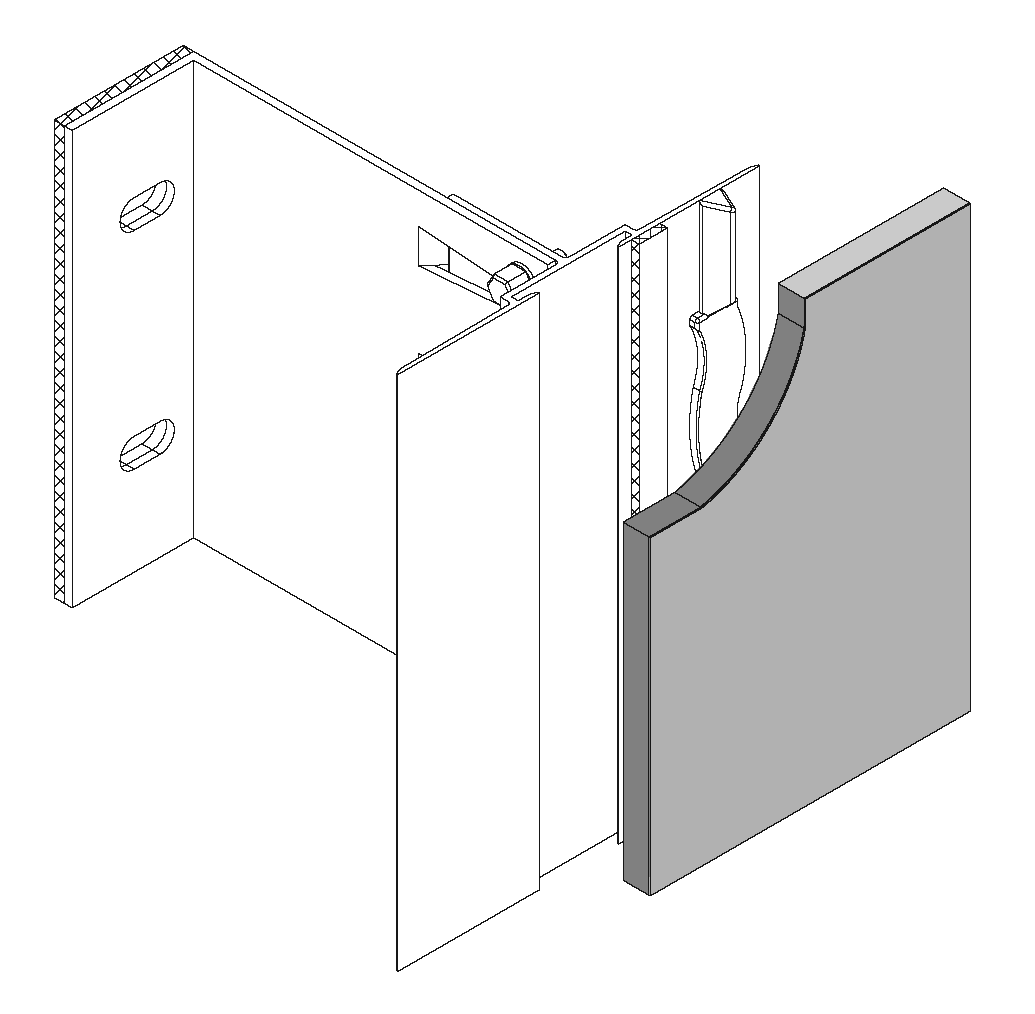

GLUING SYSTEM

The installation involves directly adhering facade panels to the substructure profiles (either aluminum or steel). The adhesive used in this system must be suitable for fiber-cement panels, ceramics, and composites.

ATTENTION!

Technical data for the panel should be verified according to the guidelines of the panel manufacturer and the manufacturer of supplementary elements.

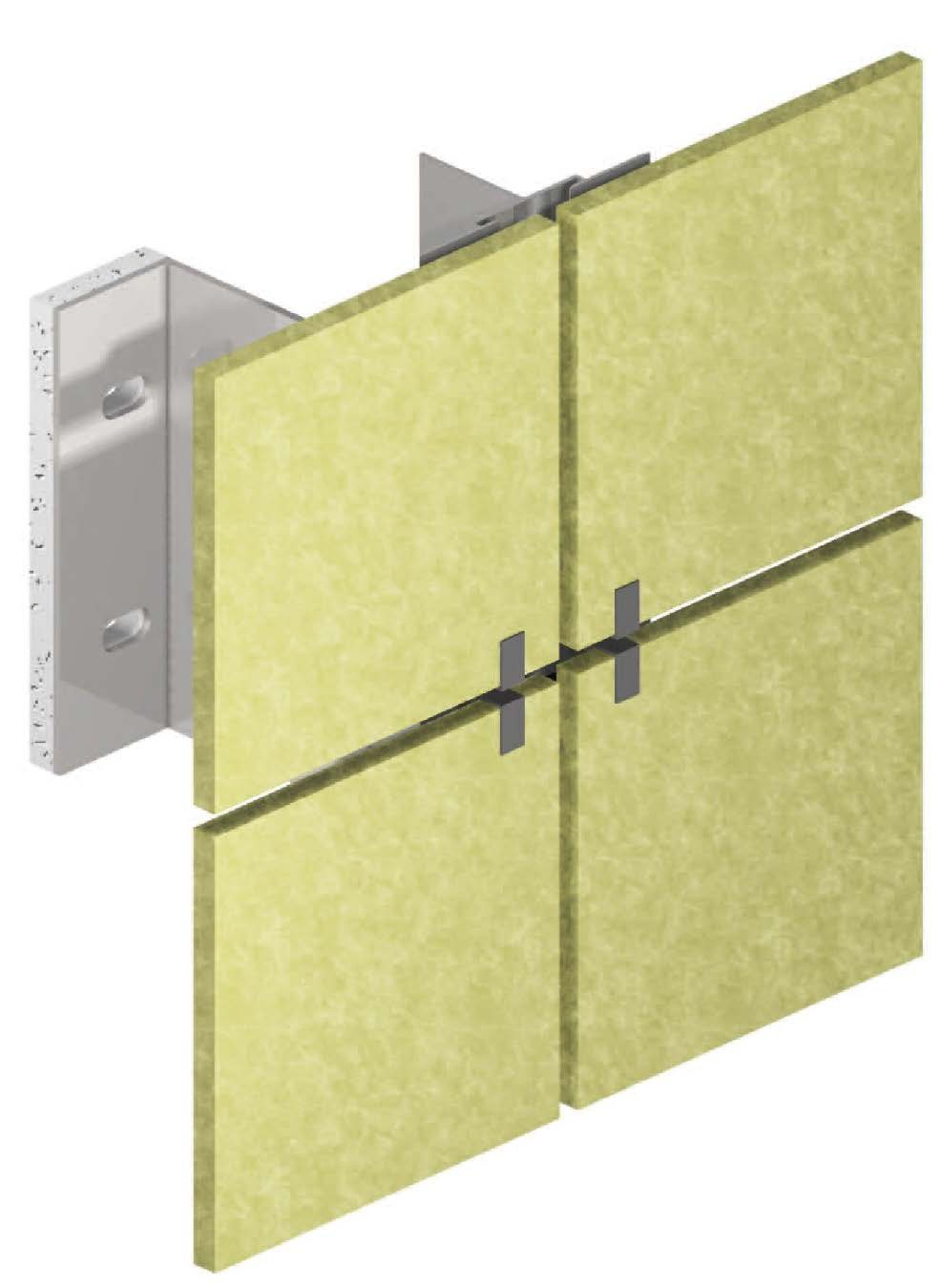

RIVETING SYSTEM

Panels can be attached to an aluminum substructure using rivets. This solution allows for the installation of panels of different sizes. For maintaining the best aesthetics of the facade, it is advisable to choose powder-coated rivets, which are available from external suppliers in a wide range of colors.

ATTENTION!

Technical data for the panel should be verified according to the guidelines of the panel manufacturer and the manufacturer of supplementary elements.

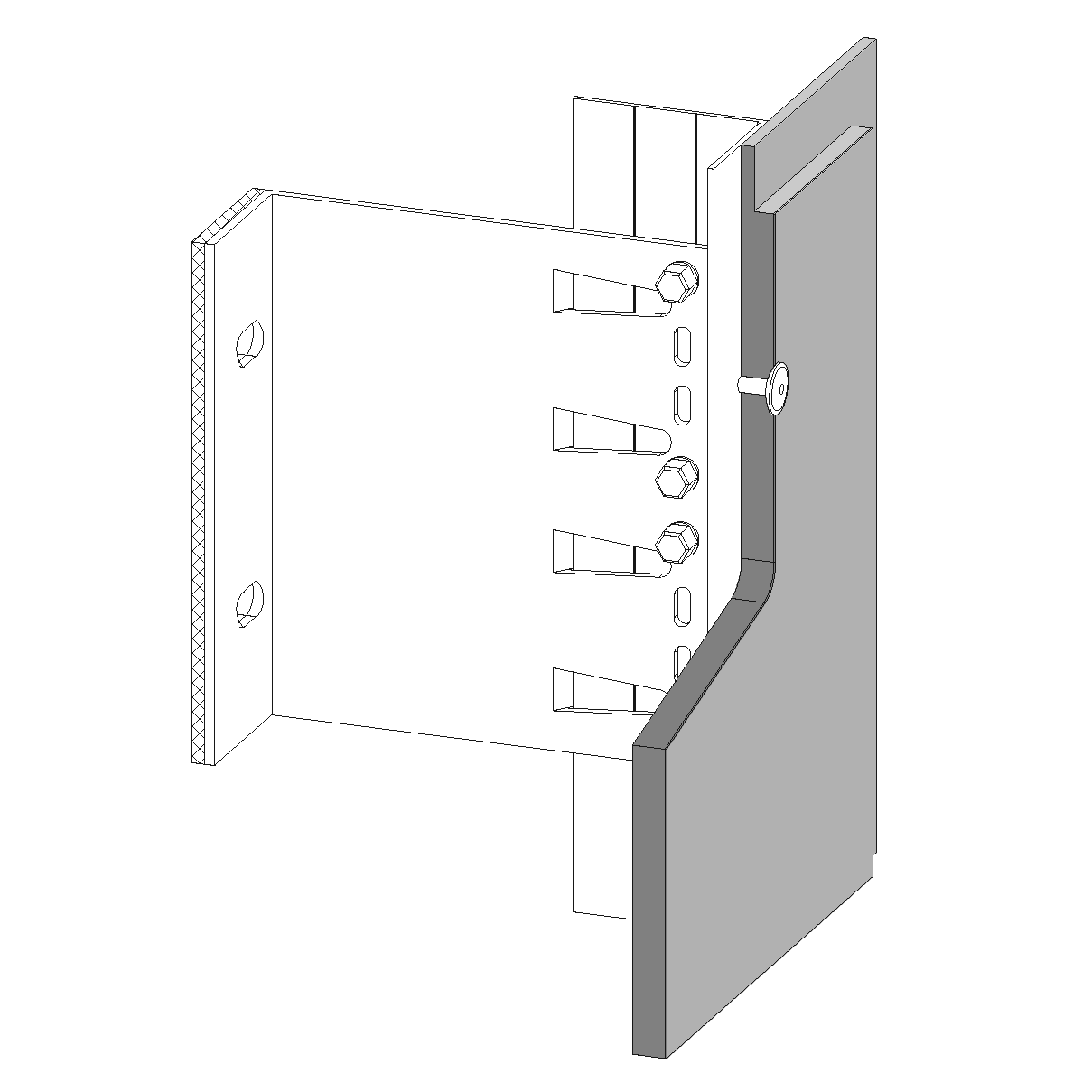

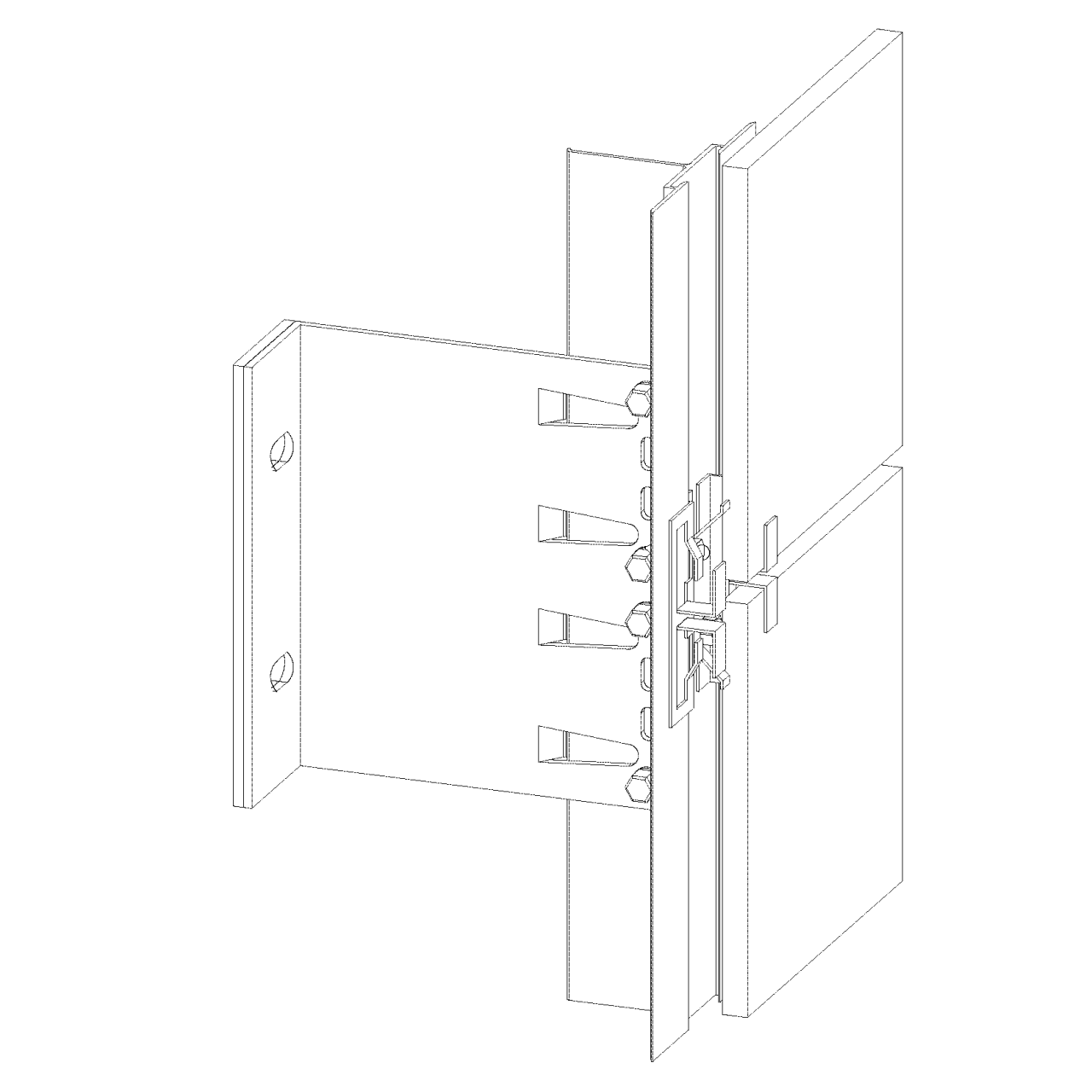

CONNECTORS (HOOKS) SYSTEM

In this system, the fastening element for the facade panel consists of special connectors with various shapes, attached to the substructure profiles (either aluminum or steel). The other substructure elements, such as profiles (Z, T, C), and brackets, are chosen independently by the installation company based on the project requirements.

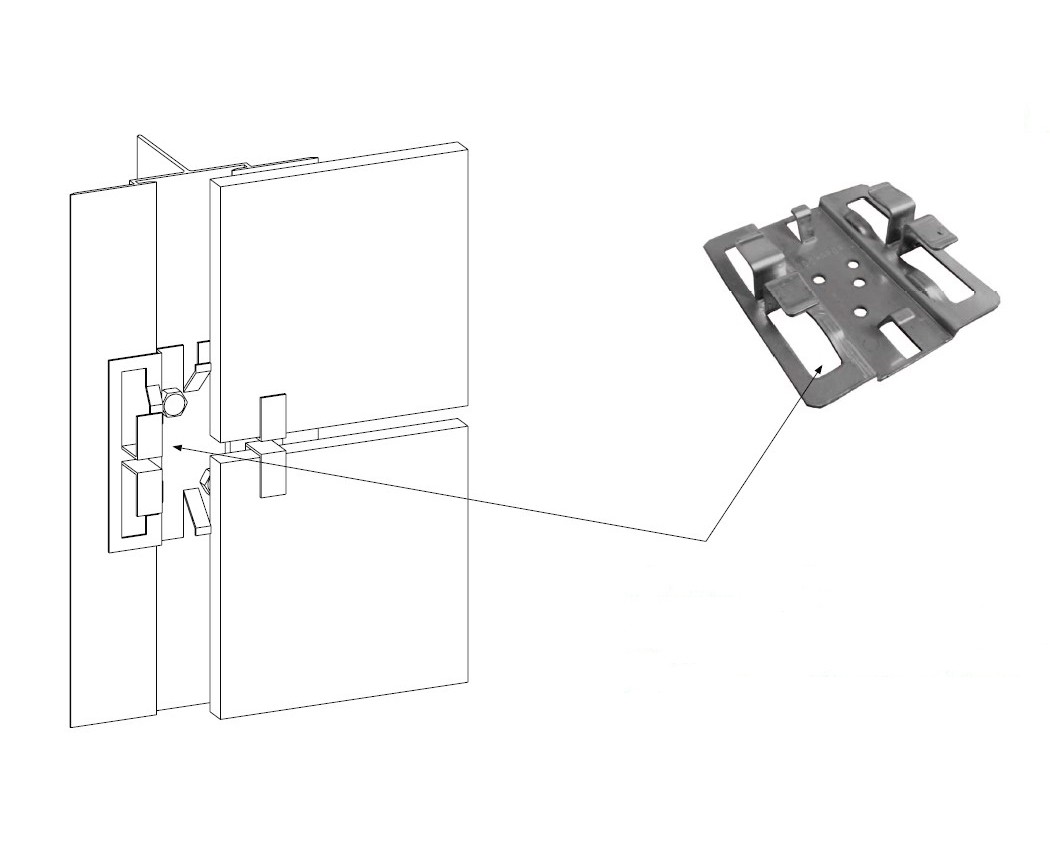

The installation of tiles on the substructure is carried out using stainless steel plates with visible tabs.

The mounting plate, attached to the substructure, enables the installation of flat ceramics with a tile thickness of 8-13mm.

We attach the plate to the substructure using screws. The indentation in the middle of the plate serves to guide it along the axis of the "T" profile - the screw head is concealed in this space.

ATTENTION!

Technical data for the panel should be verified according to the guidelines of the panel manufacturer and the manufacturer of supplementary elements.