Recommendations for storage and transport, processing methods and dimensions of Puricelli HPL slabs

References

Puricelli HPL slabs, which is a laminate produced under very high pressure and temperature conditions, is a material with a wide variety of applications. It is perfect for both interiors and exteriors. Extremely durable, resistant to mechanical damage, moisture and dirt - it is definitely a material for special tasks! In today's article we will discuss its technical aspects, related to transportation, storage or processing.

Storage and transportation of Puricelli HPL slabs

Slabs of the Puricelli brand are characterized by excellent technical properties, thanks to which they are used in many different industrial and construction sectors. However, in order to take full advantage of their potential and enjoy the highest quality for years, it is very important to follow the recommendations for storage and transport. Improper storage conditions, lack of care during transport or moving the slabs can lead to mechanical damage or deformation. The way in which the slabs are maintained from the moment of production, through storage, delivery to the installation site, affects the condition of the material at the client's site. What to pay special attention to?

- When transporting the slabs, they should be placed horizontally, on solid, stable pallets. This method protects them from bending and the risk of cracking under their own weight. In the horizontal position, the load is distributed evenly over the entire surface of the slab, reducing the risk of point pressure and associated damage. This is particularly important during transportation, when the slabs are additionally exposed to vibration and shock. This position also allows for easier access during loading and unloading and prevents uncontrolled slipping/moving.

- The edges of the slabs should be secured with additional protective accessories, such as tapes, caps, spacers, foil or cardboard covers.

- During storage, the slabs should be placed horizontally, on stable pallets, and well protected from rainfall, sub-zero temperatures and direct sunlight.

- Physical characteristics, such as thermal expansion, can make the dimensions of the slabs change slightly depending on temperature and humidity. Therefore, it is recommended to prepare the slabs and leave them for a minimum of 72 hours in the target location for adaptation before installation.

Puricelli HPL slabs treatment

Puricelli's HPL processing is simple, and the tools that are used for hardwood will suffice for this task. Cutting the slabs is the stage where carbide discs will work best (it is recommended to choose those with an additional diamond coating). To achieve a durable and aesthetically pleasing finish, the slab should be carefully milled, and its side surface sanded with fine sandpaper of high gradation. Drilling is best done with a hand drill, table-top drill or CNC machine.

Ease of processing is an important aspect not only for the assembler, but also for the customer - it affects the final pricing of the work. For example, working with some types of natural stone is very difficult and time-consuming, which significantly increases the cost of the entire installation and narrows down the specialists who are willing to undertake it.

Puricelli HPL slabs dimensions

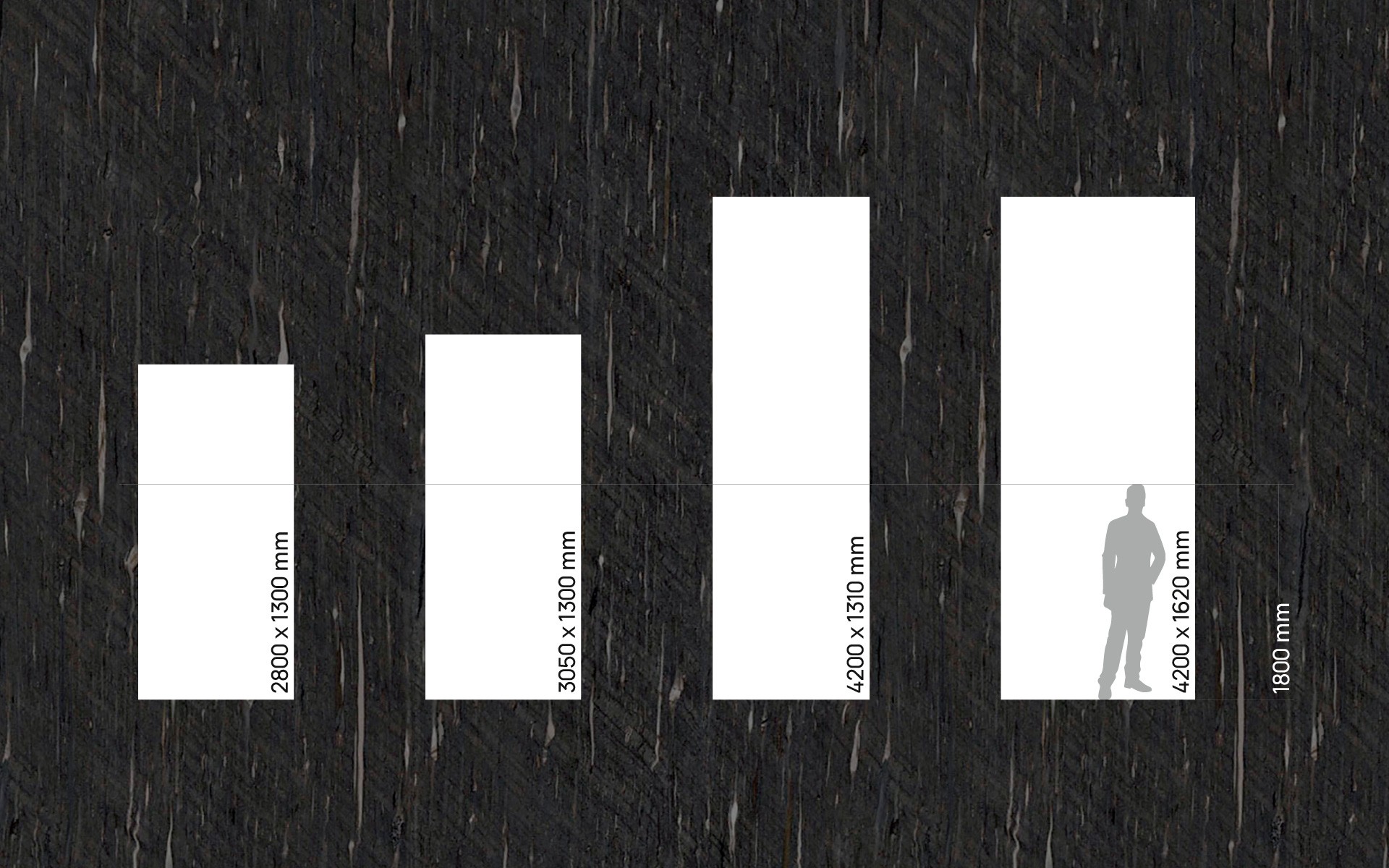

Architype offers HPL slabs with the following dimensions and parameters:

Purpose - furniture industry:

- Standard dimensions:

- 2800 x 1300 mm,

- 3050 x 1300 mm,

- 4200 x 1310 mm,

- 4200 x 1620 mm.

- More than 40 types of finishes.

- Thickness of boards: 4, 5, 6, 8, 10, 12 mm.

Purpose - interiors of buildings:

- Standard dimensions:

- 2800 x 1300 mm,

- 3050 x 1300 mm,

- 4200 x 1310 mm,

- 4200 x 1620 mm.

- More than 40 types of finishes.

- Thickness of boards: 4, 5, 6, 8 mm.

Purpose - for outdoor use:

- Standard dimensions:

- 2440 x 1220 mm,

- 2800 x 1300 mm,

- 3050 x 1300 mm,

- 3200 x 1620 mm,

- 4200 x 1310 mm,

- 4200 x 1620 mm.

- 4200 x 1860 mm (selected decors only).

- Thickness of boards: 6, 8, 10, 12 mm.

Following the above described tips will allow you to enjoy your interiors (as well as your outdoor space) intact for many years. It is also worthwhile to use the help of specialists who will perfectly advise you, choose the right type of material, and know all the nuances of working with it. Contact us for more information and/or to select an expert to help you with your Puricelli HPL slabs project.